What is a foreign body?

A foreign body is any undesirable object, not intentionally present in the food, which may compromise food safety or quality. This can include items that are obviously foreign, such as insects, stone, glass or plastics, and materials that are connected with the food, such as bits of stalk, shell, or feather.

Why are they a problem?

When a foreign body complaint is made, the manufacturer or enforcement authority has to decide if the foreign body makes the food unsafe i.e., injurious to health or unfit for human consumption, or unduly affects the quality of the product in relation to consumer perception or fair trading. If it is found to be any of these things, the manufacturer is in breach of EU Regulation No. 178/2002 and will be subject to appropriate legal and product recall actions.

Additionally, both global Food Safety Standards (as managed by the GFSI), and food industry guidelines, call for control of foreign bodies.

This blog post provides information on selection and maintenance of food industry cleaning tools and utensils, with regard to minimizing the risk of product contamination by foreign bodies.

Challenges:

Most cleaning equipment and utensils used in food production are made of plastics (including polyesters, polypropylenes, and nylons), metal (including stainless steel and aluminum), rubbers, silicones and thermoplastic elastomers (TPEs), or any combination of these.

Foreign body control in food manufacturing is often centered on the use of in-line metal detectors. Metal detection is a well-established and effective method of reducing the risk of metal fragments in commercial food products. Control of non-metallic foreign bodies is more difficult and, even with the introduction of in-line X-ray systems, detection of low-density plastics is a challenge.

This means that the major control of foreign bodies from cleaning equipment and utensils centers on the appropriate selection, use and maintenance of them. Additionally, visual inspection of the product, either manually or using an automated visual inspection system, can be used.

What do GFSI Standards say?

BRC1:

![]()

- Hazard analysis and control, 2.7.2 – ‘The HACCP food safety team shall conduct a hazard analysis to identify hazards which need to be prevented, eliminated or reduced to acceptable levels.’ This must include:

- Presence or production of foreign bodies.

- Maintenance, 4.7 – ‘An effective maintenance program shall be in operation for plant and equipment to prevent contamination…’

- Maintenance, 4.7.2 – ‘In addition, where there is a risk of product contamination by foreign bodies arising from equipment damage, the equipment shall be inspected at pre-determined intervals, the inspection results documented, and appropriate action taken.’

FSSC 220002:

![]()

- Cleaning and sanitizing agents and tools, 11.2 – Tools and equipment shall be of hygienic design and maintained in a condition that does not present a potential for extraneous matter.’

IFS3:

- Risk of foreign material, 4.12.1 – *‘Knock out’ No.6. Based on hazard analysis and assessment of associated risks, procedures shall be in place to avoid contamination with foreign material. Contaminated products shall be treated as non-conforming products.

- Site factory inspections, 5.2.1 – ‘Factory inspections shall be planned and carried out (e.g., for foreign materials). The frequency shall be based on hazard analysis, risk assessment, and experience.’

*IFS ‘Knock out’ requirements: If an auditor establishes that these requirements are not fulfilled, this results in non-certification.

Guidance available

Guideline 84, Hygienic design principles, produced by the European Hygienic Engineering Design Group (EHEDG) states that one of the functional hygiene requirements of equipment used in the food industry should be ‘prevention of foreign particulate contamination’. This requirement should be applied to all equipment used within the food production environment, particularly that which comes in to direct or indirect contact with food, where the risks of foreign body contamination is increased. This includes cleaning equipment and utensils.

EHEDG guidance on the reduction of foreign body contamination risk4,5 includes that equipment should be,

- resistant to cracking, fracturing, splintering, chipping, corrosion, flaking, abrasion and UV light;

- free of fastenings which may loosen and fall into the product;

- mechanically stable.

It should also be subject to regular inspection and replacement, as part of an effective preventative maintenance program, and be cleaned and inspected prior to use.

Unfortunately, not all cleaning equipment and utensils used in the food industry are made or used with this guidance in mind. All too often poorly constructed and un-regulated equipment is purchased or made (Figures 1-6), and equipment maintenance is overlooked (Figures 7-8).

Figure 1:

Badly designed replaceable blade squeegee.

Figure 2:

Damage caused by screwdriver.

Figure 3:

Metal screw connecting two parts of the squeegee.

Figures 4-6:

Site-made equipment utilising nuts and bolts, or tape to secure or repair equipment. Increased risk of foreign body contamination of food product.

Figures 7-8:

Poorly maintained equipment leading to increased foreign body risk from food debris, pests and bristles.

Reducing the risk of foreign bodies from cleaning equipment and utensils:

General guidance

Do choose cleaning equipment and utensils that,

- are made of good quality, solid materials that are durable and resistant to your production environment challenges, e.g. temperature, chemicals, light, food and surface types etc.

- are of a contrasting color to the food product, to enable any foreign bodies to be seen more easily (either by eye or by an automated visual recognition system).

- are free of fastenings, and

- are mechanically stable.

Don’t use cleaning equipment and utensils that are,

- made of wood or foamed plastic. Both have known durability limitations, which could present an increased risk of foreign bodies.

- painted or coated.

- damaged or badly worn.

- poorly constructed or repaired.

Always,

- clean and inspect equipment prior to use,

- conduct regular inspections, repairs and replacement of equipment, as part of a preventative maintenance program

- store equipment appropriately, e.g., on wall brackets or shadow boards, to minimize damage and minimize the risk of foreign body cross-contamination.

Control of brush bristles as foreign bodies

With regard to food industry cleaning equipment one of the most commonly cited sources of foreign bodies is brush ware, where the bristles can snap, be cut, or be pulled from the brush head, and then enter the food product.

Unfortunately, the risk of product contamination by bristles will always be present. Most food industry brush bristles are made of plastic (usually a polyester like polybutylene terephthalate, PBT; polypropylene, PP; or nylon), ranging in diameter from 0.15mm – 0.60mm. Regardless of the quality of the plastic used, or the brush construction, when these bristles are used on equipment where they can get trapped, they will snap or be pulled from the brush block when pulled. They will also be cut or damaged on the sharp surfaces of equipment, leading to bristle fragment loss.

Metal detectable plastic bristled brush ware

Brushes with metal detectable plastic bristles are now available to the food industry and are suggested as a way of preventing bristle contaminated product reaching the consumer. A number of studies6,7 have been conducted to investigate the metal detectability, durability, functionality and clean ability of these bristles.

In short, the studies showed that the metal detectable brush bristle were:

- not detectable in the presence of food and packaging

- 68% weaker and only half as elastic as standard plastic bristles (polyester (PBT)

- No more or less efficient at cleaning than the standard plastic bristles

- more difficult to clean

The use of metal detectable plastic bristled brushes may in fact increase the risk of bristle contamination of food, due to their reduced strength and elasticity, and a perception that any metal detectable bristles will be controlled via the metal detector.

You can read the poster presentation on the studies here as presented at the International Association of Food Protection. (PDF)

Bristle fixation methods

Drilled and stapled brush ware

The key to minimizing the risk of product contamination by bristles is to choose a brush that minimizes bristle loss.

For many years brushes have been made by drilling holes into a solid block of material (previously wood, now more commonly plastic) and then stitching or stapling a bundle of bristles into the base of each hole using metal wire or staples (Figure 9).

This type of brush ware is often referred to as a ‘drilled and stapled brush’.

Figure 9.

Diagram of a drilled and stapled brush construction.

If the brush is well made the metal thread or staple secures the bristles in each bundle very securely. However, in poorly made brush ware, the thread or staple used can be too loose or too tight. Too loose and the risk of bristles falling out is increased. Too tight and the risk of bristles being cut or damaged is increased and, consequently, so is the risk of bristle fragment loss.

Even if the brush is well made bristles can get trapped in the equipment being cleaned and be pulled out of the bundle. Each time this happens it creates a little more space between the remaining bristles and the staple, resulting in the remaining bristles becoming looser. The more bristles that are pulled out of the bundle, the looser the remaining bristles become, and the risk of bristle loss increases.

Resin-set, drilled and stapled brush ware

In more recent years brushes have been developed that utilize adhesives (resins), in addition to a metal fixing, to aid the security of brush bristles (Figure 10).

This type of brush ware is constructed by drilling holes into solid plastic blocks that have additionally been hollowed out. Bristles are fixed into the hole with a metal staple and liquid resin is then poured into the hollow and the holes, as a secondary method of bristle fixation.

Figure 10.

Diagram of a resin-set, drilled and

stapled brush construction.

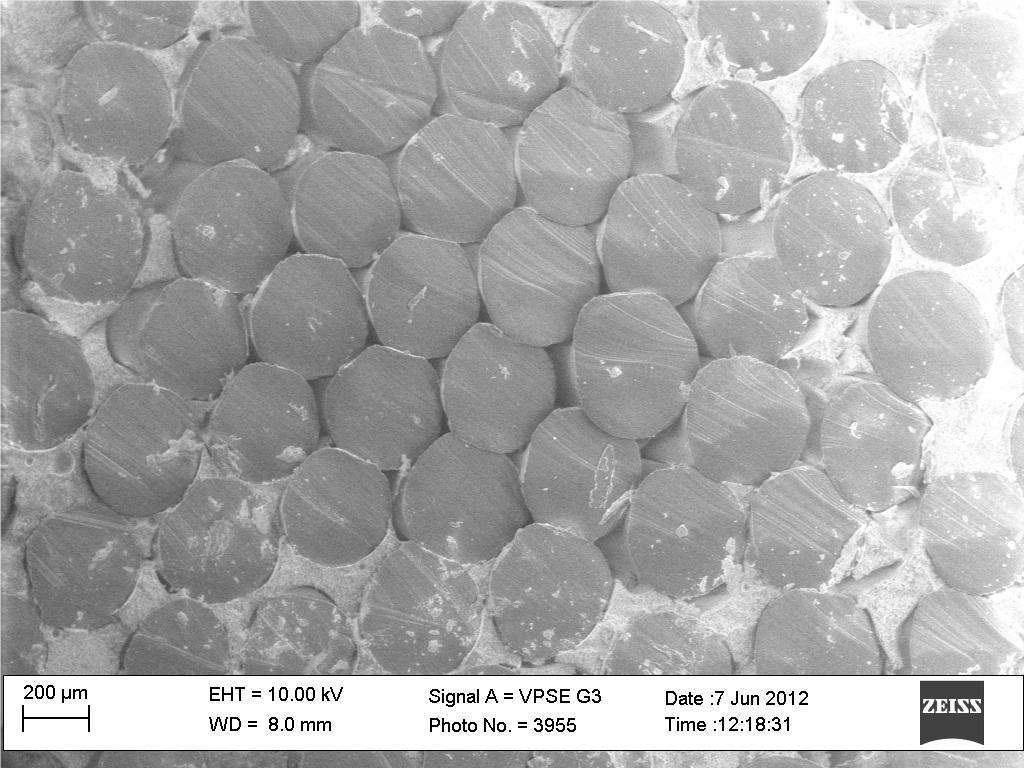

When the bristles are first fixed into the brush head they are very secure. However, investigations8 have shown that not all the bristles are secured by the resin, particularly those in the center of the bundle (Figure 11).

Figure 11.

Cross-section of a resin-set, drilled and stapled brush ware bristle bundle, showing that the bristles in the center of the bundle are not additionally secured by the resin.

Image courtesy of CampdenBRI

As with traditional drilled and stapled brush ware, with use the bristles can get trapped in the equipment being cleaned and be pulled out of the bundle. Each time this happens it creates a little more space between the remaining bristles and the staple, resulting in the remaining bristles becoming looser. The more bristles that are pulled out of the bundle, the looser the remaining bristles become, and the risk of bristle loss increases. Additionally, the resin itself can present a risk of foreign bodies. With wear and tear, and as the bristles are pulled out, fragments of resin are also released from the brush.

Fully-molded brush ware

Fully-molded bristle retention technology eliminates the use of both metal and resin in the brush construction, and thus the foreign body risk from these elements.

Each bristle in a bundle is individually fixed (by heat) within a unit (Figure 12), which is then molded into the brush head. This ensures a consistently good fixation strength for every bristle, regardless of its position within the bundle, or whether other bristles have already been dislodged.

Figure 12.

Diagram showing the construction of a

fully-molded Ultra-Hygiene Technology

(UST) brush ware

References:

BRC (2018). Global Standard Food Safety, Issue 8. August 2018.

International Standards Organisation. (2009). ISO/TS 22002-1:2009. Prerequisite programmes on food safety, part 1: food manufacturing (last reviewed in 2016).

International Featured Standard. (2017). IFS Food 6.1

EHEDG (2018). Hygienic equipment design criteria. Guideline Document No.8.

EHEDG (2005) Materials of construction for equipment in contact with food. Guideline Document No.32.

Smith, D. L., and Hegelund, H., (2016). Metal detectable plastics use in cleaning tools and utensils – does it reduce foreign body risk? Vikan White Paper.

Anderson, W., and Armstrong-Gore, J., (2017). Detectable products and materials. BST White Paper.

Smith, D.L. (2017). The hygienic design of food industry brushware – the good, the bad and the ugly. Journal of Hygienic Engineering and Design.